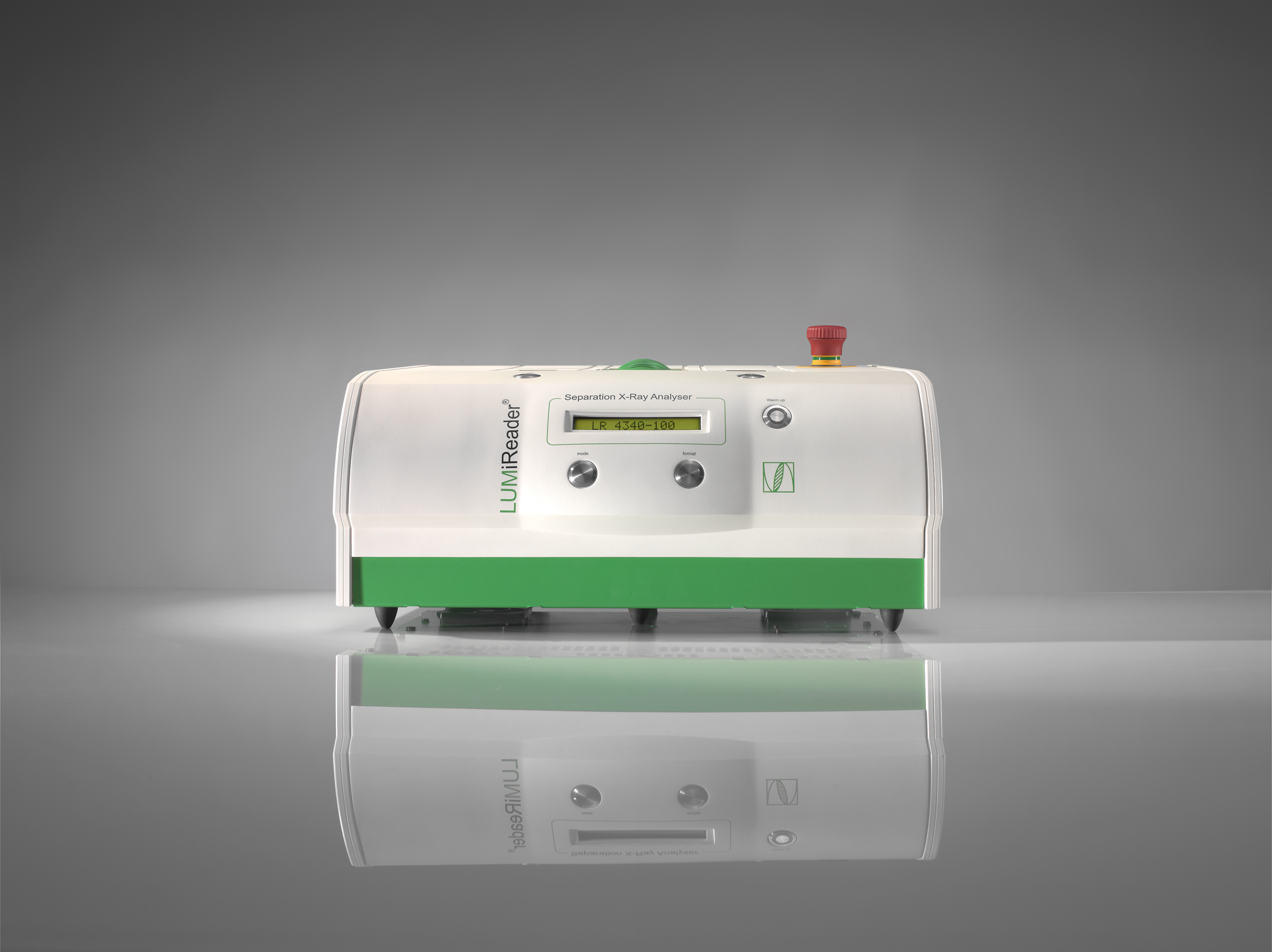

LUMiReader X-Ray - making the invisible visible

As the name suggests, the LUMiReader X-Ray employs x-rays to characterize your whole sample from top to bottom using the STEP-Technology®.

While you can use the LUMiReader X-Ray for many kinds of applications, the LUMiReader X-Ray excels in two application areas:

Stability of opaque or concentrated emulsions and suspensions

Sediment analysis for sediment caking, compaction, and resuspension

1. Dispersion Stability

Sometimes, we stumble across difficult, if not impossible, dispersions to characterize and analyze. We try and throw all the main spectral ranges, such as ultraviolet, visible, infrared, and other analytical methods, at the sample but get nowhere.

The only option is diluting, which would compromise the inherent product characteristics. For these kinds of dispersions, we developed the LUMiReader X-Ray.

Because X-rays make the invisible visible, you can measure product separation, stability, and concentration gradients. And you can do so across your whole sample.

2. Sediment Analysis

For some products, the formation of sediment layers is unavoidable. Often the result is sediment that is hard as a rock (sediment caking), rendering the product useless.

You can employ the LUMiReader X-ray to avoid such a scenario.

The X-rays allow you to see through the sediment and determine its density and compactibility. So you can design and adjust your formulation, ensuring the end-user can return the separated product entirely to its native form.

Like any other instrument, the LUMiReader X-Ray will not work for any product. Please refer to the periodic table to see which dispersion-based materials attenuate at X-ray wavelengths.

For dispersions where X-ray does work, the LUMiReader X-Ray illuminates like no other tool.

Analyze the stability of concentrated and/or opaque emulsions and suspensions directly from top to bottom

Direct. Simple. Powerful.

Measure the sedimentation and phase separation of completely opaque suspensions

Measure the creaming and phase separation of completely opaque emulsions

Specifications

Measurement principle:

Monoenergetic X-ray attenuation

Source Monoenergetic X-ray, 17.48 keV, max 20 W at 40 kV, air cooledMonochromator GraphiteDisturbance free

Radiation control requirements none; the instrument can be used anywhere

Measurement Channels: 1 sample

Volume 0.3 ml to 1.6 ml

Concentration Up to 100 Vol%, no density restrictions

The operating software SepView runs on Windows 7 & 10.

SepView is CFR-21 compliant.

Dimensions (WxHxD), Weight 47 x 24 x 44 cm3, 25 kg

Power supply 24 V, 220 W, Adapter (100 V to 240 V) included